Creating a ‘negative detail’ or ‘shadow gap’ finish is a meticulous design choice that adds a touch of sophistication and modernity to interiors, particularly when working with plywood. This technique involves leaving a deliberate gap between panels or between panels and the surrounding structure, creating a subtle, shadow-like effect. The shadow gap technique is often employed in ceilings, walls, and architectural features, offering a clean and minimalist aesthetic.

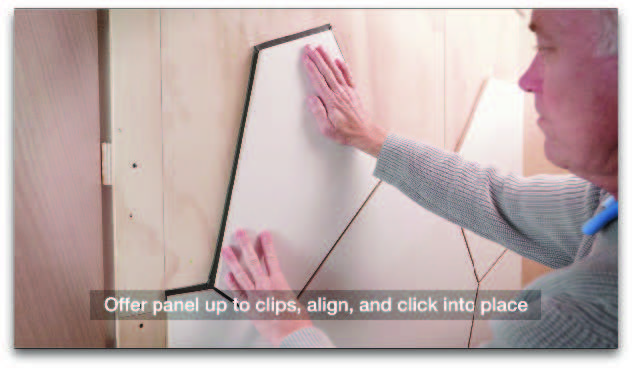

To achieve a flawless negative detail finish, our Standard Range provides the precision and versatility required. The use of PC-M1B and PC-F1A from this range facilitates the alignment of plywood panels, allowing for a seamless and consistent shadow gap. This meticulous approach ensures that the negative detail ceiling or wall features are not only aesthetically pleasing but also perfectly aligned.

Choosing a negative detail or shadow gap finish offers several advantages. It contributes to the illusion of floating panels, creating visual interest and depth. Additionally, this technique can be employed to conceal lighting elements or serve as a design feature on its own. The shadow gap architecture, especially in plywood applications, lends an air of sophistication and contemporary elegance to interior spaces.

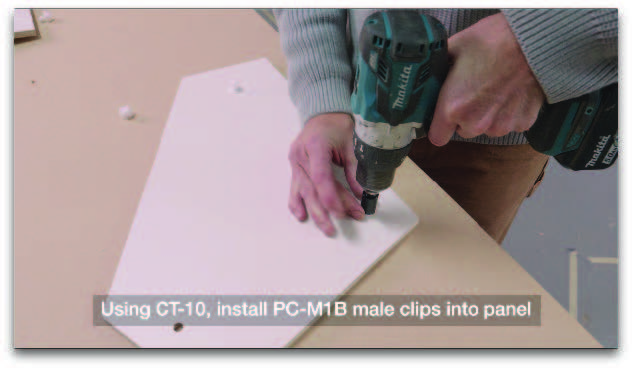

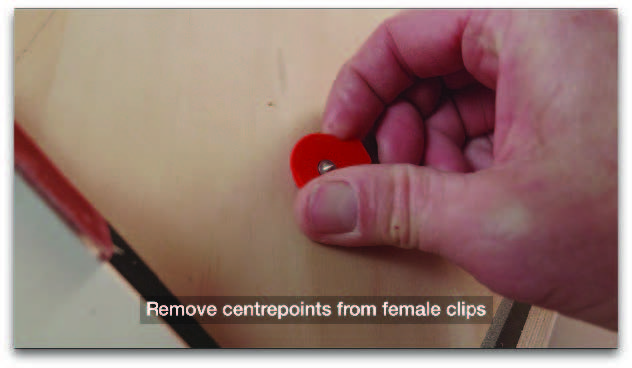

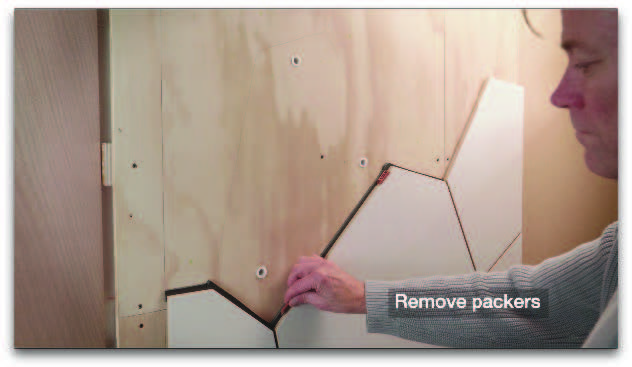

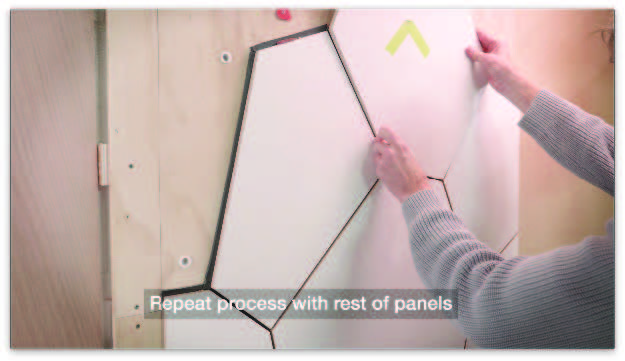

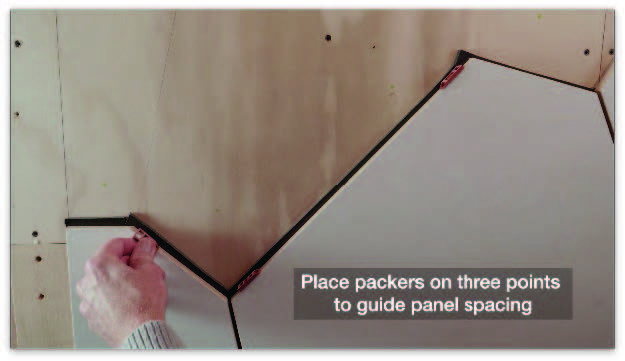

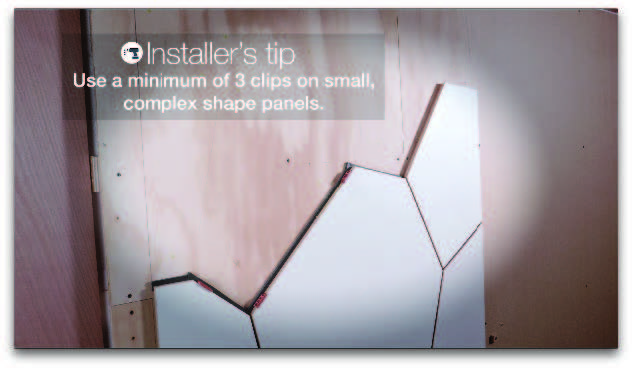

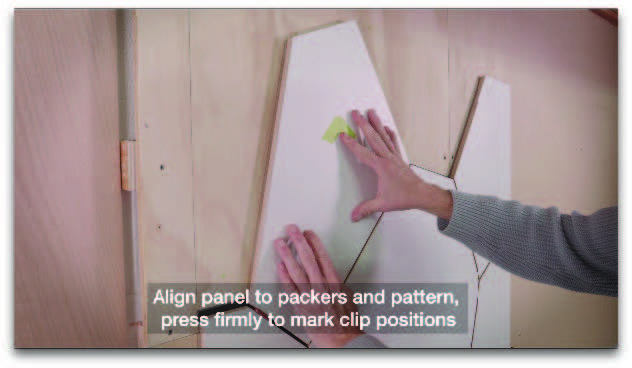

Here we demonstrate how you can use a foam tape to emphasise the ‘negative’, and how to use our Standard Range (PC-M1B & PC-F1A) to get the panels perfectly aligned.

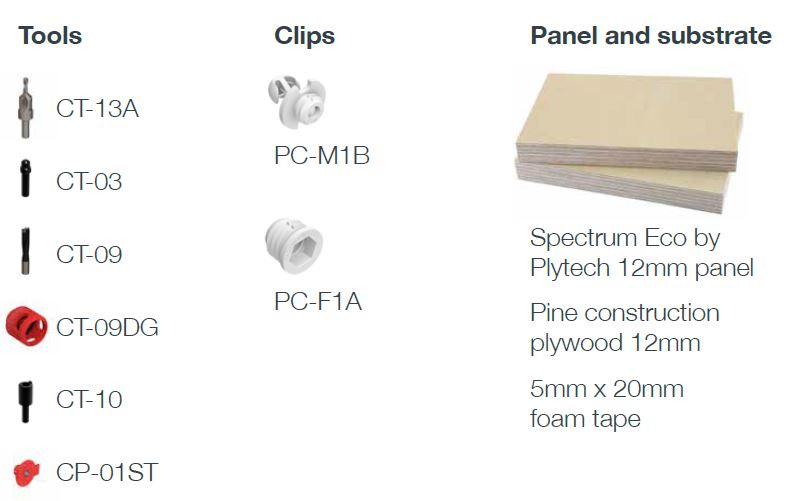

See below for tools and products required, as well as step-by-step instructions.

Tools and Products Required

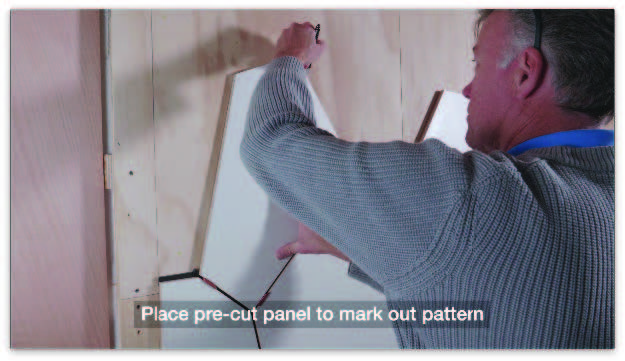

Installation Steps

Installing PC-F1A into substrate

Installing PC-M1B into panel and mounting